How to choose a PP extrusion angle profile melt pump?

When selecting a melt pump for PP extruded angular profiles, multiple factors need to be considered to ensure that the chosen pump meets production requirements and operates efficiently. Here are some key selection points:

I. Determining Production Requirements

Production Capacity:

First, clarify the production volume of PP extruded angular profiles, i.e., the amount of PP material that needs to be processed per hour or per day. This will directly affect the selection of the melt pump's displacement (CC) and rotational speed.

Based on the production requirements, select an appropriate melt pump displacement, such as 100CC, 200CC, etc., and calculate whether the actual output meets the demand in combination with the pump's rotational speed.

Material Characteristics:

The viscosity, temperature sensitivity, and other properties of PP material significantly impact the choice of melt pump. It is necessary to select a pump model capable of handling this type of material.

Pressure Requirements:

Understand the pressure requirements for the melt pump's inlet and outlet during the PP extrusion process to ensure that the selected pump can provide sufficient pressure to support production.

II. Considering Pump Performance and Stability

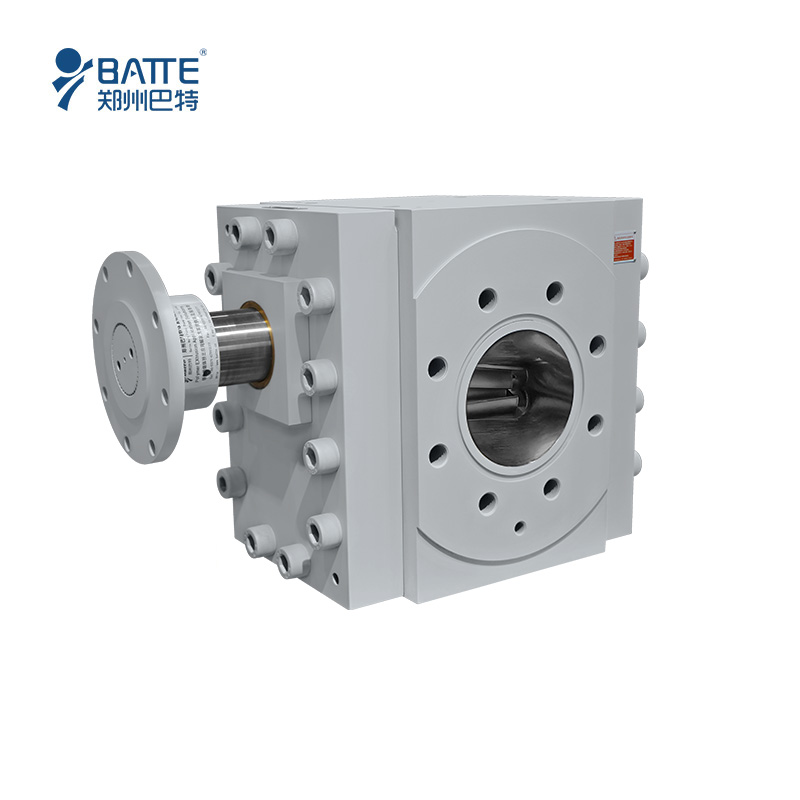

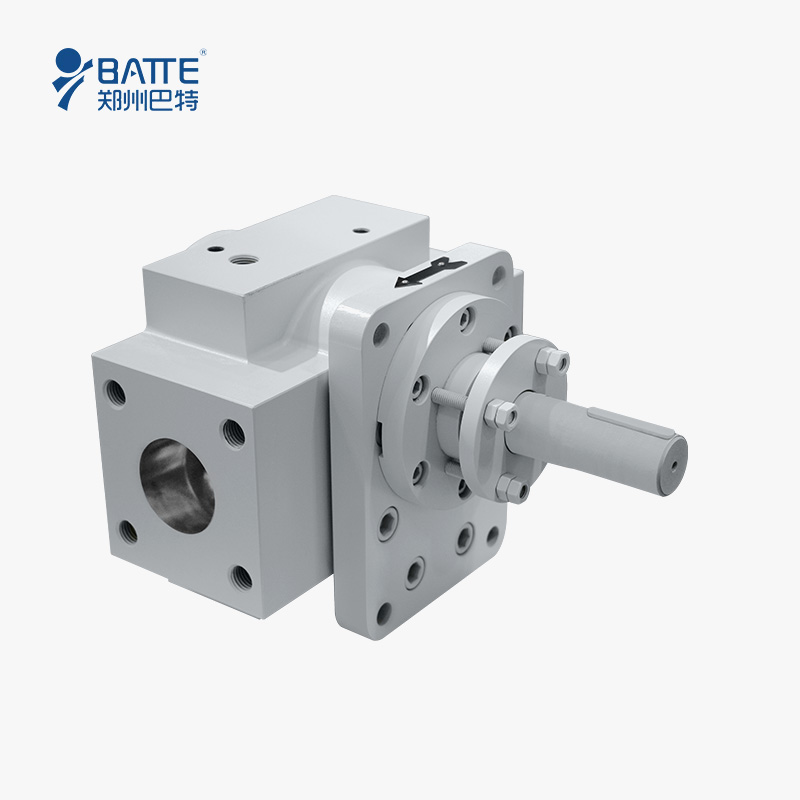

Pump Type:

Melt pumps come in various types, such as positive displacement pumps and screw pumps. For PP extruded angular profiles, positive displacement pumps are often preferred due to their stable flow rate and controllable pressure.

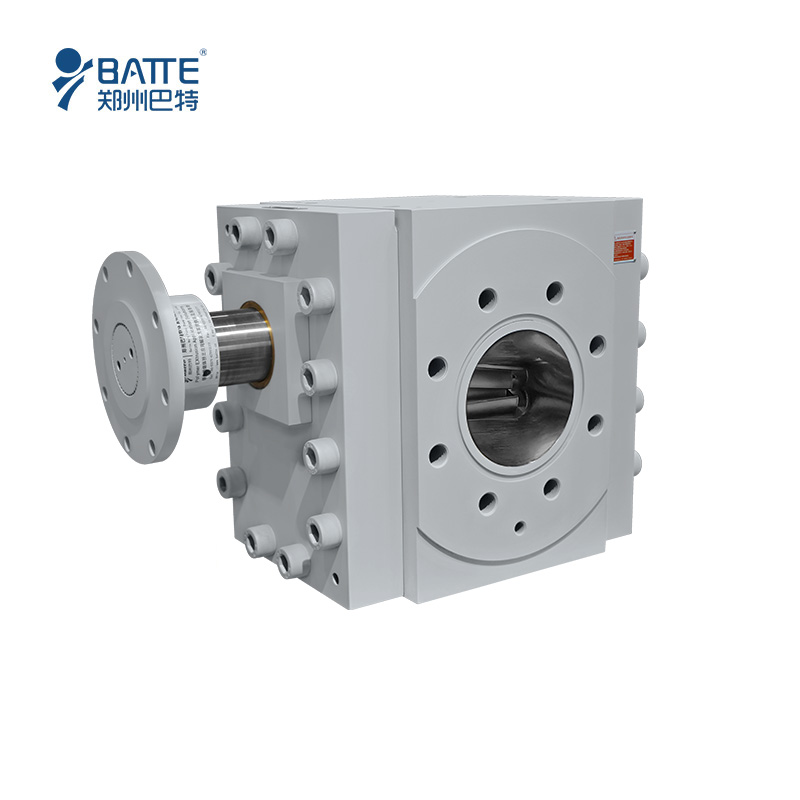

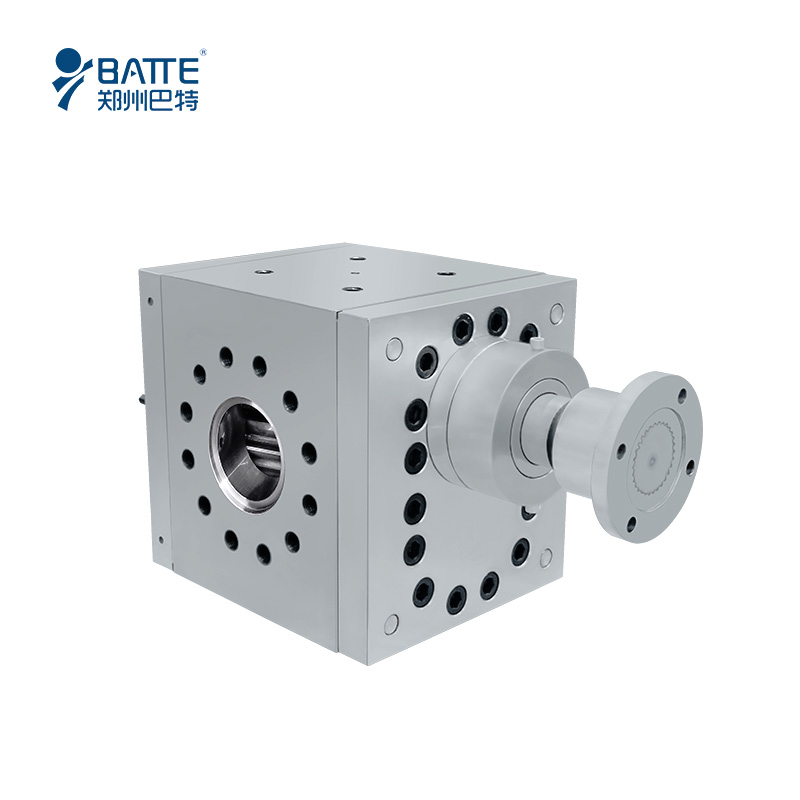

Pump Structure and Materials:

Examine whether the pump's structure is suitable for handling PP materials, particularly the heat and corrosion resistance of key components like the pump body, gears, and bearings.

Accuracy and Stability:

The melt pump needs to precisely control the flow rate and pressure of the melt to ensure the quality of the extruded products. Therefore, selecting a pump with high precision and good stability is crucial.

III. Considering Ancillary Equipment and Processes

Extruder Specifications:

Melt pumps typically need to be used in conjunction with extruders. Therefore, when selecting a melt pump, consider the specifications and performance of the extruder to ensure their coordinated operation.

Process Flow:

Understand the entire production process flow of PP extruded angular profiles, including raw material preprocessing, extrusion molding, cooling and shaping, etc., to provide a comprehensive reference for selecting the melt pump.

IV. Comprehensive Consideration of Costs and Maintenance

Purchase Cost:

Choose a suitable melt pump model and brand based on the budget. Different brands and models of melt pumps vary significantly in price, requiring selection based on actual conditions.

Operating and Maintenance Costs:

Consider the operating energy consumption and maintenance costs of the melt pump. Selecting a pump with high energy efficiency and convenient maintenance can reduce production costs.

In summary, selecting a melt pump for PP extruded angular profiles requires comprehensive consideration of production requirements, pump performance and stability, ancillary equipment and processes, as well as costs and maintenance. It is recommended to communicate with professional pump manufacturers or suppliers to customize a suitable melt pump solution based on specific needs. Additionally, regular maintenance and servicing of the pump body and its key components should be prioritized to ensure long-term stable operation and satisfaction of production requirements.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould