Installation and Use of Melt Blown Cloth Metering Pump for Extruder

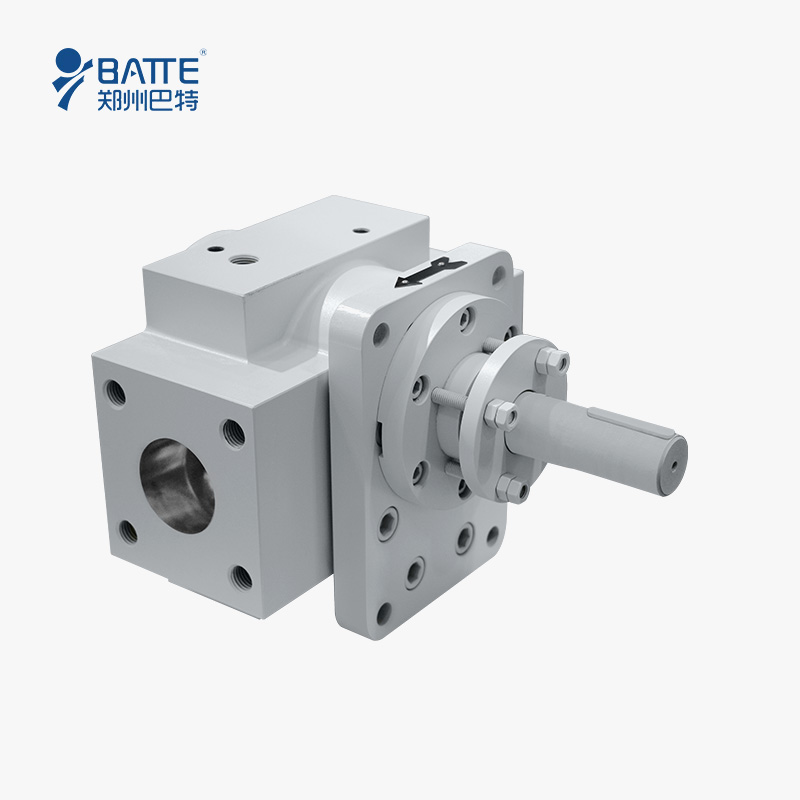

1. Open the packaging of the extruder melt blown fabric metering pump and carefully inspect it. If there is any damage or component loss, please communicate with our company immediately. The melt blown metering pump is made of high-temperature alloy steel material, and all components have undergone heat treatment with high hardness, so the material is brittle and belongs to precision equipment. Any impact or fall may cause damage, and it is recommended to use lifting rings for installation.

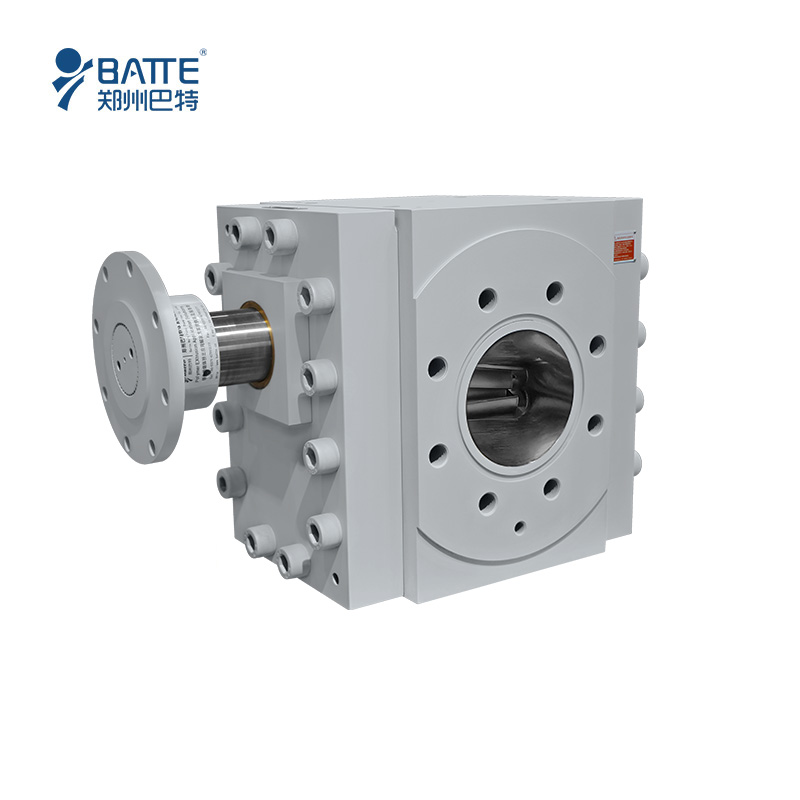

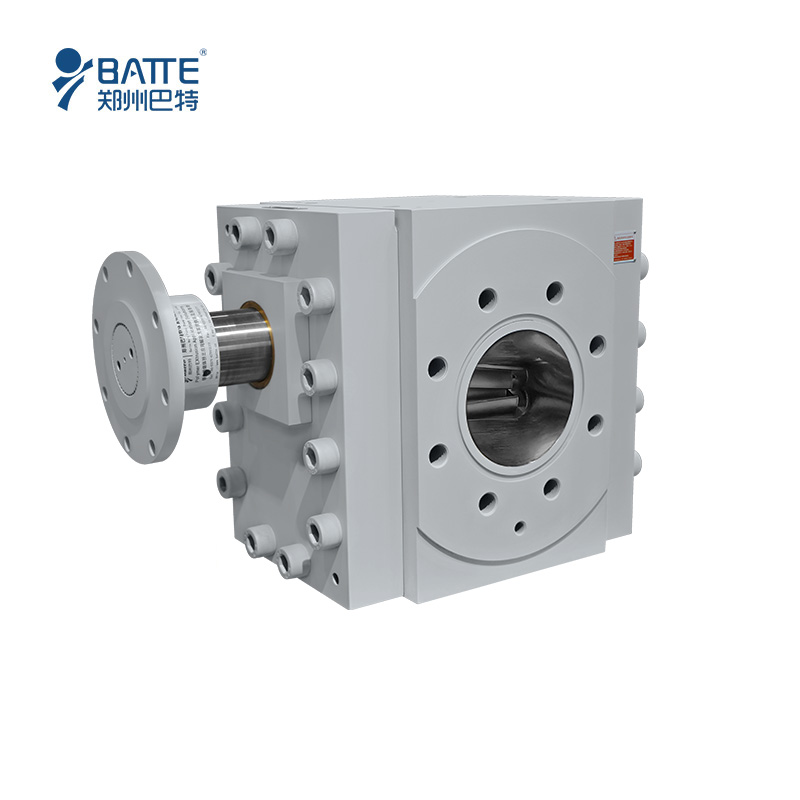

melt blown fabric metering pump

2. Please accurately distinguish the inlet and outlet of the extruder melt blown fabric metering pump during installation. When the equipment is correct, the pump shaft rotates clockwise. When installing equipment motors, reducers, universal couplings, and pumps, the fixed base of the pump should be firm to ensure the concentricity between the pump base and the motor drive shaft, and there should be no jamming during operation. Otherwise, it will cause gear jamming, and in severe cases, the drive shaft may crack.

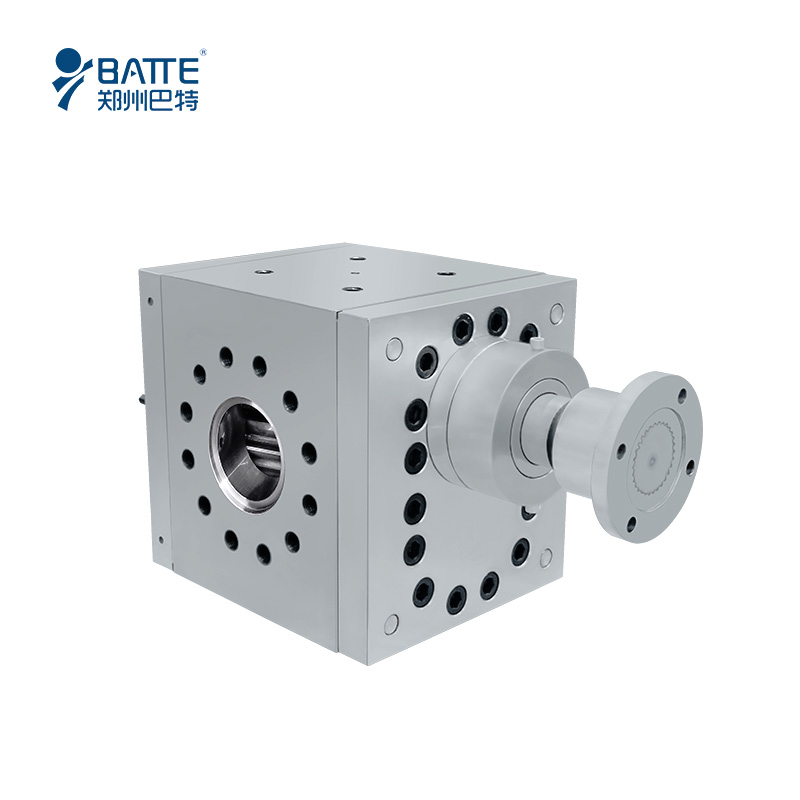

melt pump extrusion

3. There are pressure sensor holes and temperature sensor holes left on the surface of the pump body. If the sensor is installed correctly, the measurement data may show errors. The connection of the pump body adopts high-strength bolts to ensure safe operation of the pump body.

melt blown fabric melt pump

4. When starting the pump, it should be operated at low speed. After the pump operation is stable, it can gradually be adjusted to normal speed and pressure. If the pump runs unevenly, it is necessary to stop the pump and check the cause to avoid severe damage inside the pump. The sealing of melt blown fabric metering pumps usually uses packing seals, and it is necessary to frequently adjust the orientation of the sealing cover to ensure that the pump sealing condition is always in a good state.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould