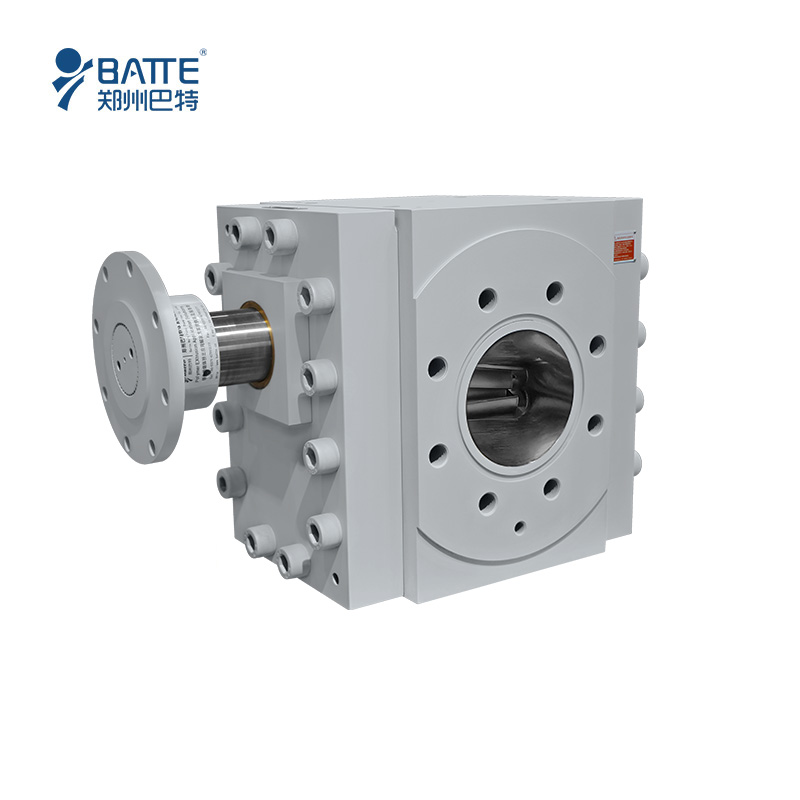

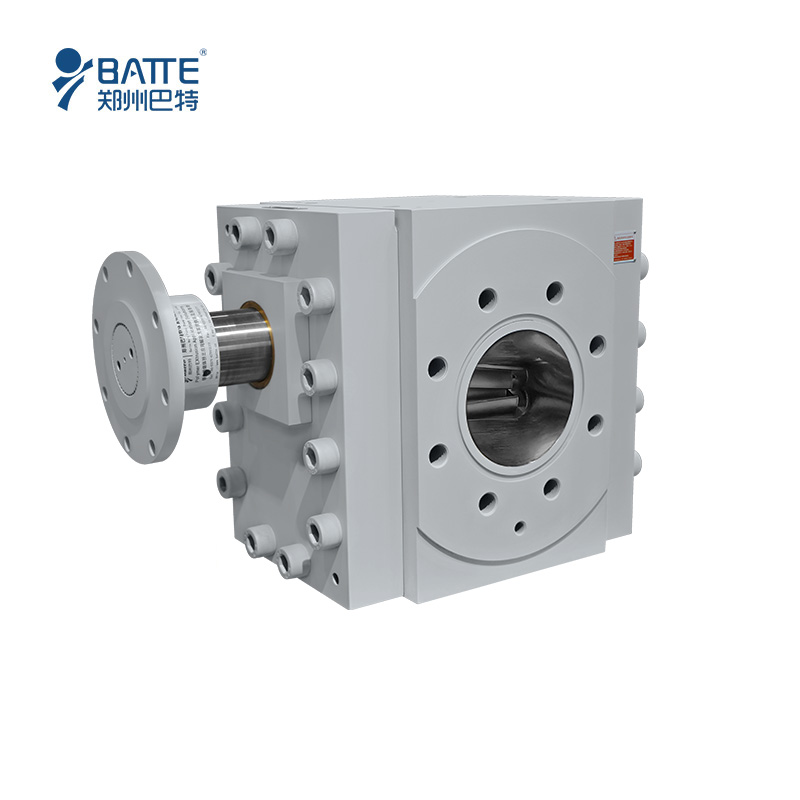

PVDF sheet melt pump

Introduction to PVDF Sheet Melt Pump

PVDF sheet melt pump is a professional engineering plastic for polyvinylidene fluoride resin (PVDF). PVDF can be used to produce insulation skins for pipes, sheets, films, substrates, and cables. Highly non reactive thermoplastic fluoropolymers are transported, pressurized, and metered.

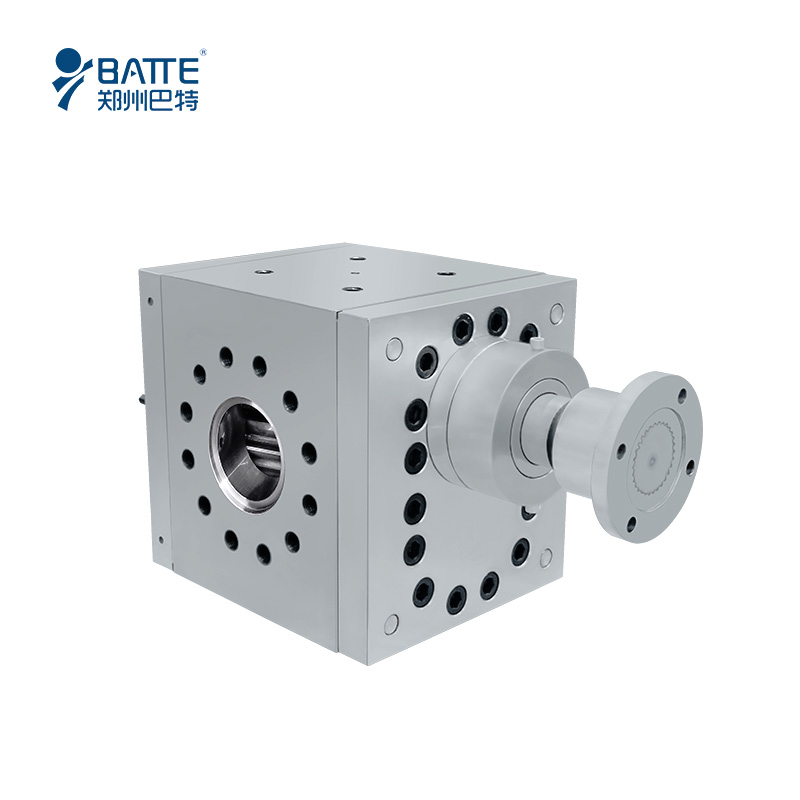

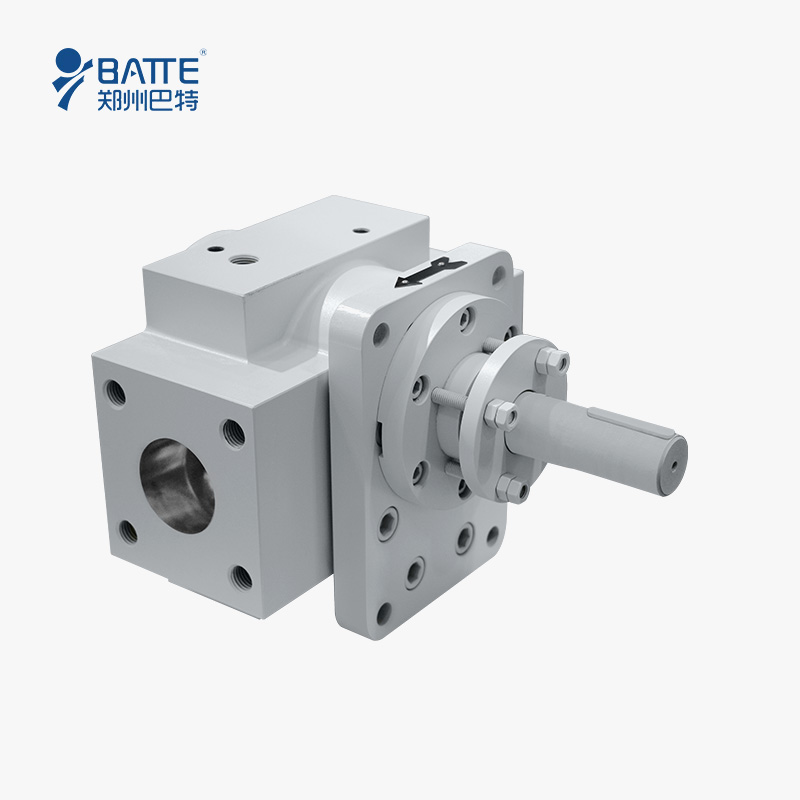

Structure of Polyvinylidene Fluoride Resin Melt Pump

PVDF melt pump mainly consists of pump casing, driving gear, driven gear, sliding bearings, front and rear end plates, packing seals, etc.

Advantages of Thermoplastic Melt Pump

1. Optimized tooth shape design ensures more stable transportation with minimal fluctuations.

2. The flow channel design without dead corners, without material residue.

3. A simpler sealing method.

4. Optional wear-resistant configuration, suitable for high filling conditions.

Sheet extrusion melt pump parameters

Transmission medium viscosity: 1-40000Pas

Suction pressure: 0-30MPa

Output pressure: 0-40MPa

Allowable pressure difference: 25MPa

Operating temperature: ≤ 350 ℃

Heating method: electric heating

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould